Short pitch precision roller chain

As one of the roller chain manufacturers, suppliers, and exporters of mechanical products, We offer roller chains and many other products.

Please get in touch with us for details.

Mail:[email protected]

Roller Chain

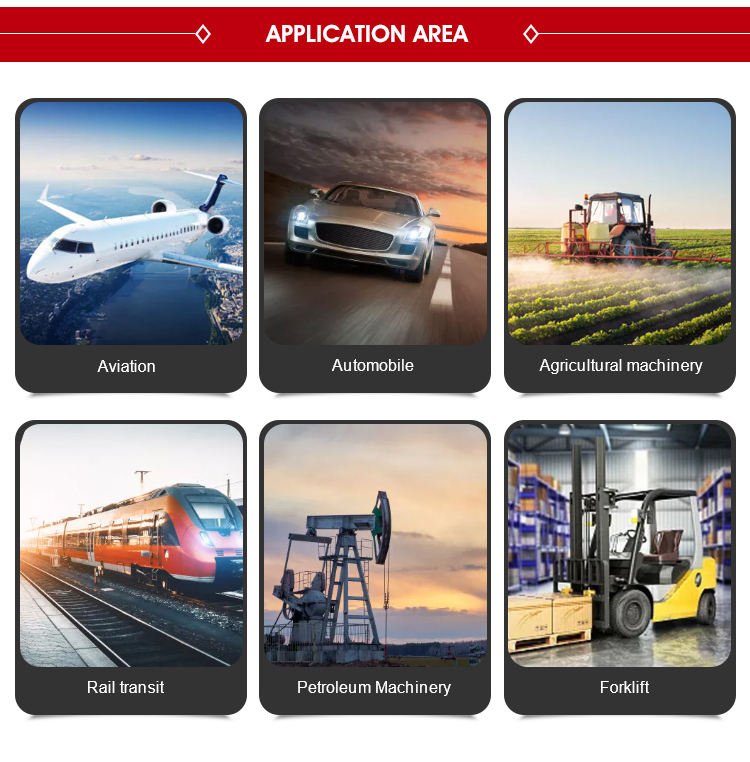

Roller chains are a type of mechanical chain that is widely used in power transmission applications. They consist of a series of cylindrical rollers that are connected by links, which are then wrapped around sprockets to transmit torque and rotational speed between two shafts. we offer a range of high-quality roller chains that are designed to deliver reliable and consistent performance in a variety of applications.

Roller chains are a versatile and reliable type of chain that can be used in a wide variety of applications. They offer a number of advantages over other types of chains, including high load capacity, smooth operation, durability, and a wide range of applications. When choosing a roller chain, it is important to consider the load capacity, speed, and environment in which the chain will be used. With proper maintenance, roller chains can last for many years.

Roller Chain Specifications

|

Pitch

|

Roller

diameter

|

Inner

width

|

Plate

thickness

|

|

P

mm

|

d1

mm

|

b1

mm

|

T

mm

|

|

6.35

|

3.3

|

3.18

|

0.8

|

|

9.525

|

5.08

|

4.68

|

1.2

|

|

12.7

|

7.92

|

7.85

|

1.5

|

|

15.875

|

10.16

|

94

|

2

|

|

19.05

|

11.9

|

12.57

|

2.5

|

|

25.4

|

15.88

|

15.75

|

3

|

|

31.75

|

19.05

|

18.9

|

4

|

|

38.1

|

22.2

|

25.22

|

5

|

|

44.45

|

25.4

|

25.22

|

6

|

|

50.8

|

28.58

|

31.55

|

6

|

Roller Chain Benefits

High load capacity: Roller chains can transmit high loads without slipping or breaking. This makes them ideal for applications where heavy loads must be moved, such as in conveyors and lifting and material handling equipment.

Smooth operation: Roller chains run smoothly and quietly, even under heavy loads. This makes them a good choice for applications where noise is a concern, such as in machine tools and robotics.

Durability: Roller chains are durable and can withstand high loads and shock. This makes them a good choice for applications where the chain is subjected to harsh conditions, such as in outdoor environments and in applications where there is a risk of impact.

Wide range of applications: Roller chains are used in a wide variety of applications, including conveyors, machine tools, lifting and material handling equipment, robotics, and automotive applications. This makes them a versatile and cost-effective choice for many different applications.

Uses Of Roller Chain

Conveyors. Roller chains are a common choice for conveyors because they are durable and can handle a lot of wear and tear. They are also relatively quiet, which is important in some applications.

Lifting and hoisting equipment. Roller chains are used in lifting and hoisting equipment to transmit power from the motor to the load. They are also used in winches and other devices that require a high degree of strength and durability.

Machine tools. Roller chains are used in machine tools to transmit power from the motor to the cutting tool. They are also used in indexing tables and other applications where precise movement is required.

Motorcycles and bicycles. Roller chains are used to transmit power from the pedals to the rear wheel in bicycles and motorcycles. They are also used in some cars and trucks.

Agricultural machinery. Roller chains are used in agricultural machinery to transmit power from the engine to the various components of the machine. They are also used in conveyors and other equipment used in agriculture.

Maintenance tips for Roller Chain

Inspect the chain regularly. Look for signs of wear, such as stretched links, missing or damaged rollers, or bent pins. If you see any of these signs, the chain should be replaced.

Lubricate the chain regularly. The type of lubricant you use will depend on the environment in which the chain is operating. In general, you should use a lubricant that is compatible with the materials of the chain and sprockets.

Keep the chain clean. Dirt and debris can build up on the chain and sprockets, which can increase wear and tear. Clean the chain regularly with a mild detergent and water.

Adjust the chain tension. The chain should be properly tensioned to prevent excessive wear and noise. If the chain is too loose, it will slap against the sprockets, which can damage both the chain and the sprockets. If the chain is too tight, it will put unnecessary strain on the components, which can also lead to premature wear.

Replace worn sprockets. Sprockets wear out over time, and if they are not replaced, they can damage the chain. Worn sprockets can also cause the chain to skip or jump, which can lead to accidents.

We are one of the best roller chain manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!